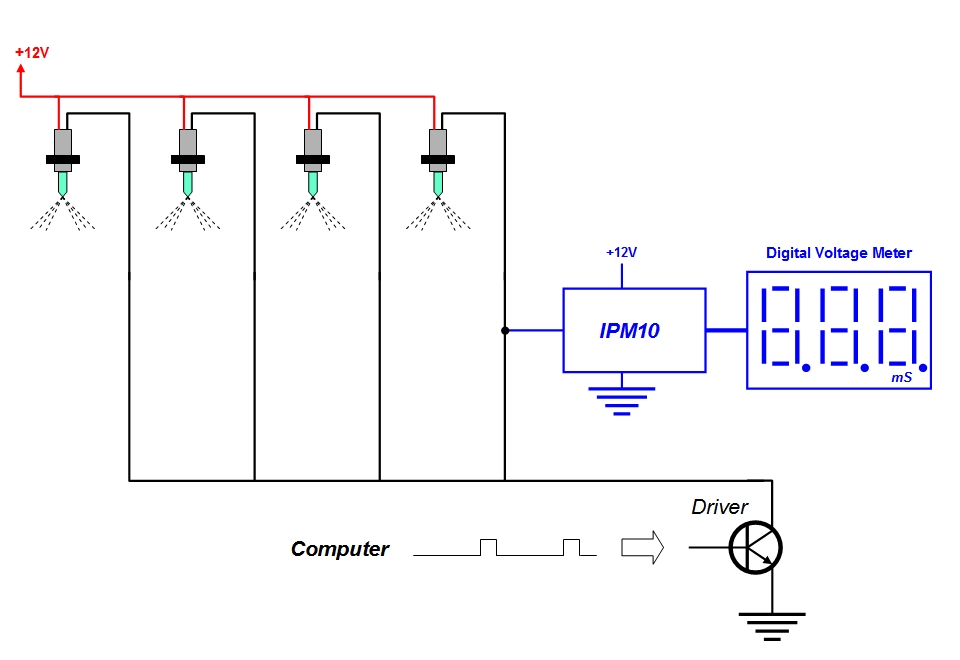

Since my present gasoline car not is electronically limited to regulate the fuel amount, I can skip the use of pulse extenders. An IPE-GS makes no good and the FFG module that reads opening time has expired. Despite this, the opening time of the injector can change if one starts experimenting with different low-energy fuels and additives.

The solution to that problem is to use an individual instrument that measures opening time. Some multimeters may be useful but if one want a fixed installation that does not occupy unnecessarily large space and can be used whenever it is interesting to note variations - then it just remains to constructing such a circuit itself and it is that what this project is about.

I had already deployed a cable that was supposed to an RCW together with a IPE-GS, but when it became apparent that this circuit was superfluous, the cable was instead serviced a DVM from an IPM10 located at the ECU in the engine compartment. It is a custom made aluminum box that holds a DVM and a switch. The IPM10 measures milliseconds by one decimal. The minimum measurable opening time is 0.5 mS and the highest 13 mS.

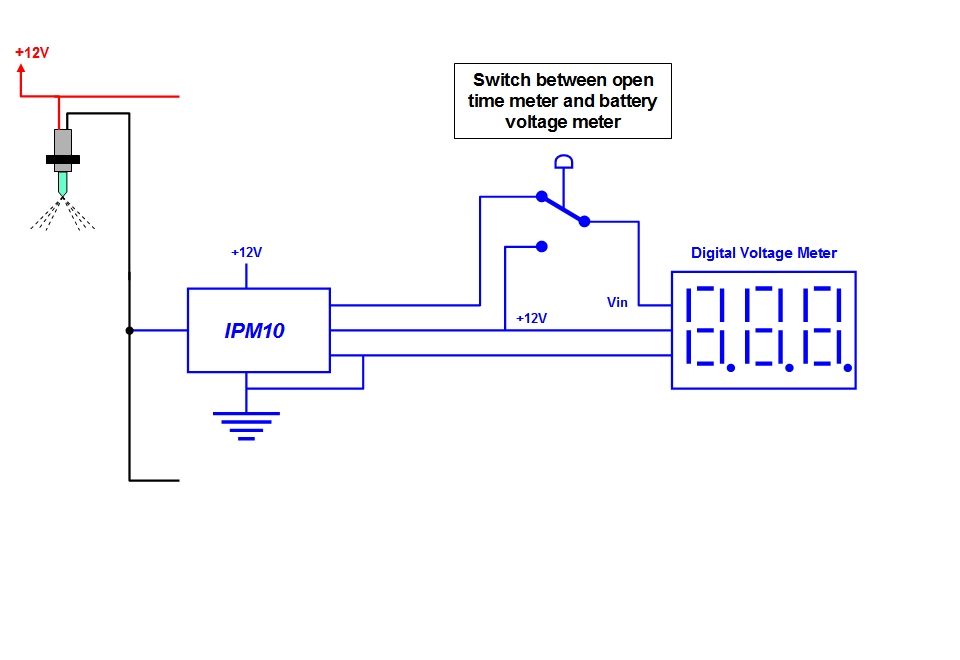

I bought the DVM device at Kjell & Company for only 10 bucks and am a clever little contraption, which despite its small size can measure 0.0 to 99.9V with high accuracy and under various adverse circumstances. This thing can replace the volt measurement for my VAD design (however not the current measurement)...

A funny feature with IPM10 in its basic version is that it does not reset itself if the injector pulses suddenly stop. The numbers on the display begin to walk away if the input becomes high - for example in the case of a motor brake. Finally, the maximum voltage (13V or 13mS) is reached. If the input is constant low, for example when the engine is switched off (key position two), then it slowly moves down to a low value. To counteract this one can use the Z module.

If you have bothered yourself to enrich your instrumentation with this metering device, you should kill two birds with one stone and supply the DVM with a switch so that the battery and generator voltage also can be checked if desired.

If you want to look closer on this thing you can download it here:

In the zip-file can you find everything required to implement it (manuals, diagrams and PCB-files)

- except to realizing it.

| IPM10#A-2 |

# A-1 Is the first audit.

# A-2 Is equipped with a fan control module FC10 designed to control computer fans. Such a fan can be used like a compressor before the air filter - to increase a car's performance.