However, I had to make holes in the bottom to make the 2.5l can fit. One should be able to fill it with new fuel from a proper fuel can as well. I do not think I could find a more suitable sheet metal box than this one. The legs follow the package if you are a little bit ingenious - turn them around and attach with rivets instead. When it is a little bit shaky it adjusts when the surface is uneven - it is always steady. The fuel consumption for two burners in operation is approximately 35-40 ml E80N per hour and 70-80 ml for all four.

It should be mentioned that this construction unfortunately is unsuitable in environments where there are children or animals. The risk of fire and devastation is imminent if someone bumps into this device during operation so that it breaks and fuel leaks out. For commercial purposes must the fuel be free from flammable components such as gasoline and everything must be done robust and enclosed, not in the rickety/spidery manner as the tank and the burner are arranged here.

Since the heating power with two burners mostly is enough so it is seldom necessary to use all four. All burners use copper cuttings (instead of sand bed) as a catalyst, which minimizes air pollution. What smells is most lamp oil - implicitly: the more burners in use the more smell. I use two clamps (the cheap variant) to prevent fuel from reaching the two rear burners. If I want, I can only run a single burner with a third clamp.

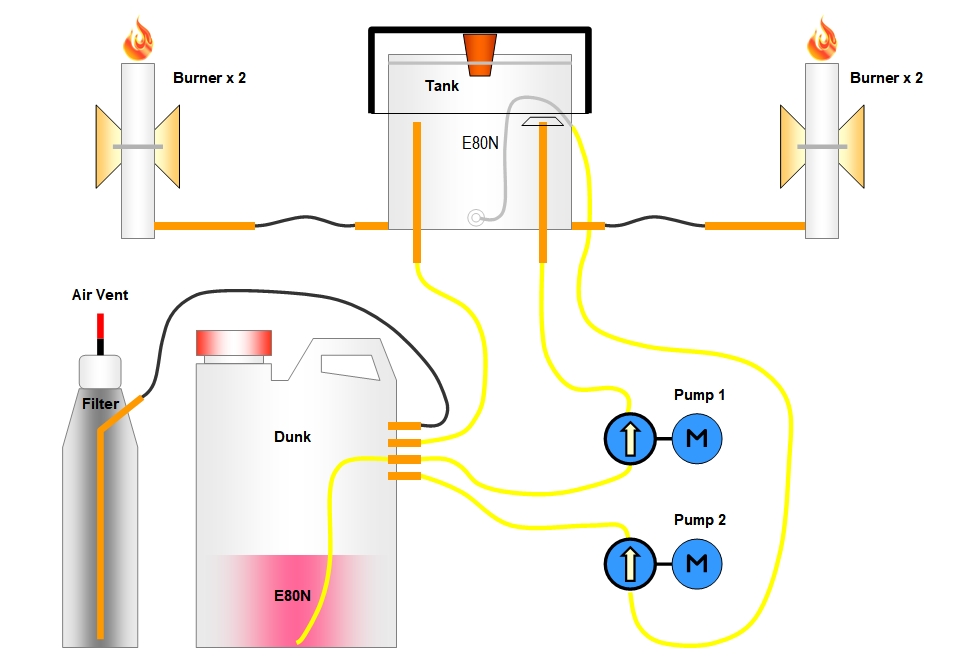

The specific feature of EHB-C1 is that it uses fuel pumps intended for RC hobby use to transport fuel towards and away the tank (the white/black container located in the center between the burners). The tank was originally a can for preserved pears.

One pump for filling and one for emptying. This pump brand I use here leaks fuel when it's not in operation, so one can not use just one pump. If that were the case, the fuel would slowly flow backwards to the can again, so far one would not use valves? The pumps are powered by a 12V battery from Biltema of lithium ion model. Only mechanical electronics are required to realize this, however the automation is based on an timer circuit that fills up the tank with fresh fuel every two hours. The time interval the pump is on can be set differently for different designs and conditions - regular cmos technology and a relay make this possible. One disadvantage of the automation is that the noise scares when the pump suddenly starts.

The black upper part of the tank is a piece of a plastic pipe (sewage) with a round polycarbonate disc inserted. This object rests on the red plug and causes a small pressure on top so that the tank remains airtight. However, the actual purpose of the upper part is to act as an additional fire barrier in case any burner would start firing flames next to the tank - a purely safety measure. This scenario can occur if one walks past the flames that start flattening or if one move the EHBn during operation. The fastening arms with which the burners are stuck are layered on the Lixhults cabinet ceiling with M6 screw, nut and plastic washers (so that the paint is not removed). Each burner can be fold inward so that they are better protected when this device is transported or stored during the summer. The hose between the tank and each burner is purchased on Conrad and by the brand Kavan (207196). Since the burner and the inlet and outlet of the tank are 4.8 mm brake pipe of copper, transitions must be made. Such can be arranged with a shrink tube, which by the way is highly chemical resistant. The yellow fuel hose for remaining drawings is also purchased on Conrad (Pichler 1436845), as well as the pumps (Modelcraft 207894).

Download circuit diagram and PCB file: EHB-C1 Revision A-1.

The burner cork or what to call them is very important and ensures that the burner does not leak bad smell into the room when the appliance is off. They look like English bearskin caps and originated in a bicycle handle I found at Bauhaus (2950997A) - they are very heat resistant and gas-tight. The top of each cap is sealed with a round aluminum piece and black silicone adhesive. Since the E80N fuel does not like to build up pressure in a closed container, it is not as important to ensure that the ventilation is working. However, venting should be done in operating mode when the fuel is consumed. Before the vented air (gasoline vapor) comes out so must it first pass a half-liter bottle filled with activated charcoal. This plastic bottle can be seen behind the can into the cabinet. In operate downtime can the air vent be closed with a small red silicone plug. Can be found behind the blue drain button.

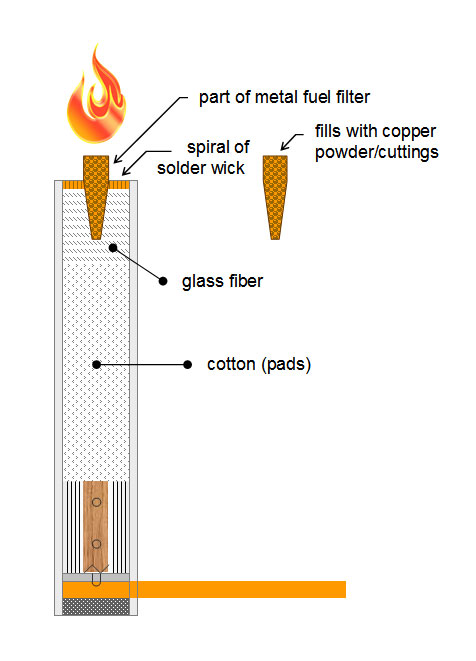

There are different ways to design the burner top so that it consists of copper. With my two extra burners I can test other constructions and instead of a copper pipe it also works with a filter insert of compressed metal grain (from a fuel filter). This along with a piece of soldering braid provides a self priming top of copper.

|

| |

|

| |