An e-hybrid burner or EHB that I will continue to mention this creation is 100% built to generate heat at the most convenient, efficient and clean way without regard to matching the interior or from any other aspect than to function - this as an EHB is anything but beautiful. The fire unit is completely okay but together with plastic bottles and tubes deprives the overall impression. But what cares a frozen apartment owners about that when there is an inexpensive, effective and environmentally method to generate a little heat? Again, we can talk about a ”poor man's wood stove”, for this is what the project is about and an EHB corresponds to this name very much.

It should be mentioned that when using an EHB arises a fire hazard. If the fuel accidentally starting to burn (in the tank or

in the bottles) is an immediate risk that it all results in a serious fire. Never leave an EHB out of sight and ensure that necessary safety equipment in form

of fire extinguisher is nearby.

I have not been able to find anything like it online so I guess this design is one of the first of its kind. To begin with, it can be concluded that an EHB with two burners represent at least three candles in heat-output, but it smells not more than a faint odor of lamp oil. No gasoline smell can perceive from the time one lights up the burners until the fuel is empty. This is not entirely correct because there be some petroleum-smelling smoke when one blow out the burners. Even when one fill the fuel bottle with new fuel emits some gasoline fumes and if one forget to seal the burner or turn off the gas filter when this thing is stationary. If one let an EHB burn out of fuel creates odors right at the final stage due to the flame smallness. Therefore, one should always seek to empty the tank and blow out the flame when the EHB should be turned off. An EHB can be somewhat complicated to build for those who do not have the right tools and equipment.

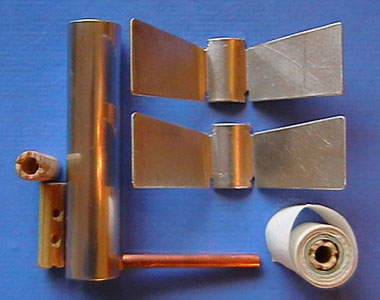

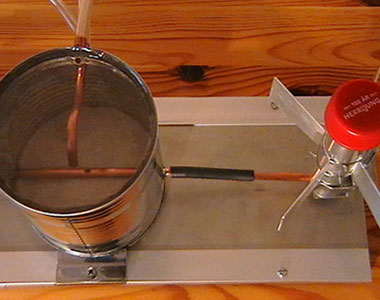

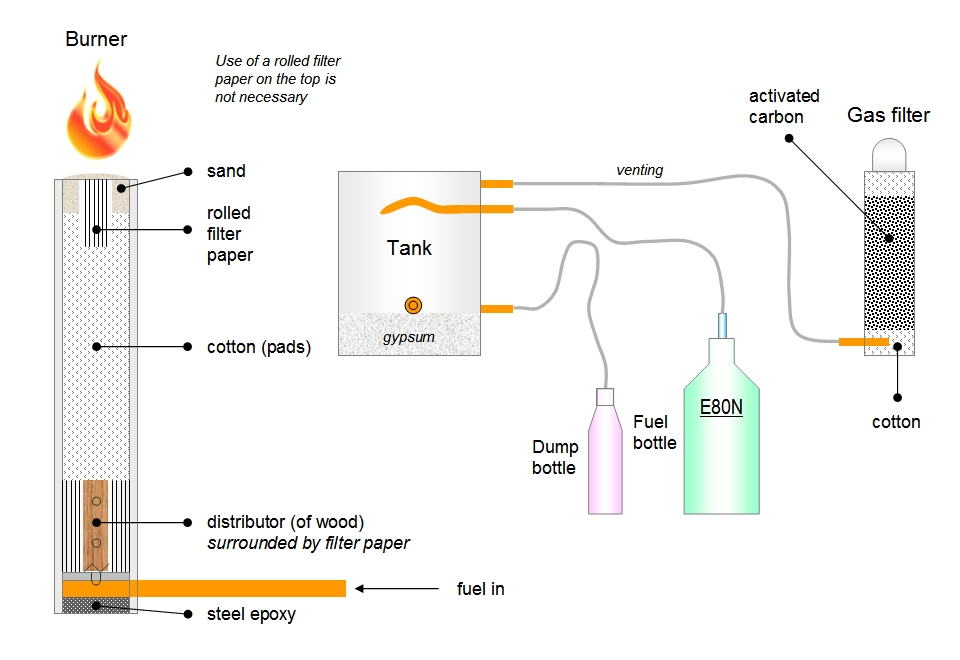

The apparatus consists of a fire unit and its peripherals which these three images illustrate. One can see that the flame size is

different despite the both burners are virtually identical. When it was several years since this construction was built (2012),

I now know the reason. What determines the size of the flame is solely the resistance the material constitutes for the flow of the fluid into the burner tubes.

The density of the distributor, filter paper and substantially the cotton determines the size of the flame. If the cotton is packed harder in one burner (than

in the other), the flame becomes smaller there and vice versa. More information about this is further down the page. That the height of the burners can be

adjusted on this particular construction does not matter when it comes to the ”flame size”. When this page was created I not fully understood all aspects

that are essential for a good function. However, it can be noted for this EHB that the height of the burners relative to the tank can be adjusted, but without

there being any specific meaning with this. I had to put everything together otherwise would not the photos be good - under normal circumstances are

the distances greater.

An e-hybrid heater is very easy to operate and to produce its fuel is a piece of cake, compared to E-spirit. The special fuel for an EHB I called E80N and consist of 80% of E85. The greatest concern is to get hold of the necessary motivation to cobble together the piece, because this might be a while. However, it is quite difficult to fail due to the absence of critical moments. All parts in the construction of an EHB are roughly of the same difficulty level. These elements are four in number: Tank, burners, fire table and peripherals.

The fuel tank can be divided into four components

- Tin for Dole pineapples (chunks)

- Brake pipes of copper to solder with ordinary solder

- Ballast - a mixture of gypsum and gravel lying in the tins bottom

- A dense transparent cap made of polycarbonate plastic

Jars with pineapple and similar fruit content tend to miss the white impregnation many other jars have. The size is a diameter of around 80-90 mm. The gypsum can be cast directly in the tin but it can be difficult to get it flat if you skimp on water. This ballast allows the draining of the fuel to be raised by about 20 mm so that there are margins to adjust the burners. The first time one filling the tank with fuel so will it mosey a while. Polycarbonate plastic has the glaziers and you sure can get it cheap. The cap must be glued and the only glue that stands up in this environment is Steel epoxy. It can also work with liquid gasket. If the cap consists of a 2 mm thick polycarbonate disc, so there is space to put the paste on top, in the same way as when putty window.

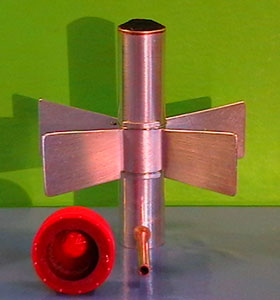

The burner can be divided into five components

- Aluminum tube with a length of 90 mm and a diameter around 20 mm

- A brake pipe which is glued with Rapid epoxy and then covered with Steel epoxy adjacent to a stopper

- Contains: Filter paper rolled on a distributor, cotton padding plus a piece of rolled filter paper again

- The combustion takes place in a rounded top which consists of fine-sifted sand

- It is important that each burner is equipped with cooling fins with the same size as the images shows

The burner design is the essence of how an EHB works. The cotton soaks up fuel like a wick, which then burns up over the sand bed. The loose sand becomes harder and darker after a period of use. The temperature rises with the height of the burner and is of course lowest where the fuel comes in.

The lower part of the burner was measured at one occasion and was 55 degrees Celsius, while the upper part was between 65-70 degrees

Celsius. The temperature is thus quite evenly distributed throughout the tube.

The fuel is preheated while it is transported to the top with the

help of the aluminum pipe which is favorable from a combustion point. The cooling of the tube is very important! Ceases the cooling becomes the burner

overheated so its contents are pushed around like a fountain of fire, and then is an uncontrollable fire near lowing. At the second picture one can see three

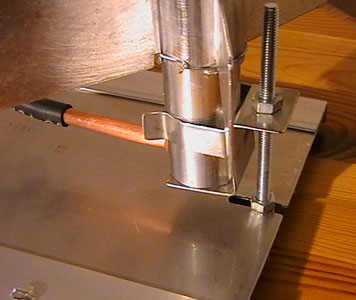

distributors (of wood) outsourced at different angles, but it is only a need for a single one (per burner).The fire table can be divided into four components

- Rectangular piece of sheet metal (preferably stainless) - usually found at metal scraps

- Two strips of for example aluminum which stabilizing the table (riveted or screwed)

- Brackets for burner holder and for the tank

- Two burner holder with the required M4 screws that allow adjustment/tuning of burners

The dimension of the sheet metal piece that I chose was 320 x 110 mm and seems to be just the right size. The burners that are adjustable in height can also be adjusted a bit in length as the distance shrinks if you move the burner up and down relative to the tank. For this reason must one make a slot for a (tall) M4 screw on both sides of the pieces outer edges which may be 15 mm long. As new knowledge (2017) has been obtained about what determines the size of the flame, there is no reason to vary the height of the burners as described here. The two burner holders are made of the same sheet as the fire table and consist of cutout pieces that are bent as shown in the right image. The tank is fixed with two metal pieces of thinner sheet via two screws, which are also attachments for strips. The way how the tank should be attached can probably be done in several ways, but one should not do damage to the lower part more than necessary. Any type of feet under the table is appropriate - I attached two plastic spacers (with double-sided adhesive tape) on the underside of the fire table and pressed then there four adhesive feet.

The peripherals can be divided into four components

- A one-liter plastic bottle (consisting of E80N) with any form of nipple - similar as for battery water

- A dump bottle to drain the tank before shutdown (dosing bottle)

- A gas filter which is connected to the tank venting

- Homemade molded silicone plugs shall be placed on the top of the burners - to prevent gas leakage

As a gas filter I use a bottle for removing nail polish that ICA (a supermarket) sells and is perfect for this purpose - with its cork one can open and close the venting hole. A bottle designed for battery water works well as a fuel reservoir as the naphtha content in E80N is too small for the plastic shall damaged. A good dump bottle can be difficult to obtain. The dosing bottle that holds 500 ml is absolutely outstanding. The observant have noticed that I use pvc hose to and from the bottles. PVC hose works pretty well for quite a long time but after a year begins it to harden and should be replaced. The hose between the tank and the burner I bought at Kebo (old swedish chemical store) for a long time ago - it's called Iso Versinic and is highly chemical resistant.

Operation

The fuel tank that sits on the fire table is like a buffer but it is in the fuel bottle the fuel primary quantity is localized. The start up of the heater begins with to opening the gas filter and then lift, turning and squeezing out the fuel from the fuel bottle into the tank. If one ended the last using to dump the remaining fuel in the dump bottle can one empty its contents before resorting to the fuel bottle, but never tap the dump bottle entirely because it gets too light and therefore unstable when it shall be on the same level as the fire unit at operation. It takes a special technique here - one have to open the cork just after one squeezed in order to avoid that the fuel is sucked back into the bottle again. It's enough to just fill the fuel tank less or to the half when the consumption is relatively low. At exit should the tank always be emptied! Is there fuel left in the tank so will it by the capillary force flows out from the burners. When the heater is not used must all parts be sealed.

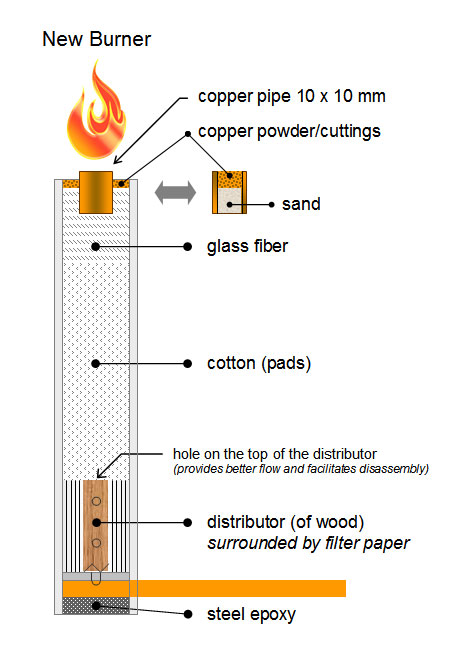

New burner design

In 2017 I managed to achieve more efficient combustion by changing a burner's upper part. If one use ethylene glycol as an additive

together with E80N so is there a risk of unburned residues. The residues can form soot that eventually clogs - so the flame shrinks. In the end, the burner

stops working because the sand bed becomes gas-tight. Another synergy effect with the new design is that the height of the flame easily can be adjusted by

changing the height of the copper pipe.

I discovered that it is the burner's interior that controls the flame size for the old construction with a sand bed. It is not the

burner height in relation to the tank. By interior I mean how much resistance the cotton part constitute for the transport of fuel to the top. Studies have also

shown that no rolled filter paper is needed - one can rely on the sand capillary forces. The cotton resistance varies with the brand. If one does not want to

fill the burner with regular cotton, then use pads. However, some manufacturers offer problems because the pads not only consist of cotton but also of other

material(s). The brand that I think is most suitable is Eldorado. Pack it soft!

In the upper part of the new burner shall cotton be replaced with fiberglass / glass wool. Then place a short blunt of copper pipe partially embedded in fibreglass at the top. The higher the tube is the higher become the flame - two millimeters are good. If the pipe stick up more than this can the flame be very high - up to the double length of the burner is no problem. The pipe is then filled with fine sand, but on the top lays copper powder or cuttings. Even outside the pipe will it be cuttings. The hot copper layer catalyses the combustion so that only an inconspicuous amount of unburned residue is passes.

Today's naphtha-based lighter fluids are more and more like lamp oils. From an operational point of view is it only positive if one can choose to drive with 20% n-paraffin (lamp oil) for the same price as for yesterday's fluids.

If one dosing 0.5% red glycol (type G+) in a batch of E80N so will it means a further improvement of the indoor air. The glycol (which is similar to G14a) has shown positive effects and can be recommended. However, avoid water in E80N!

The new EHB-C1 Heater Box is equipped with this type of burner that can be studied more closely by selecting ”H e a t e r B o x” on the top.

In the upper part of the new burner shall cotton be replaced with fiberglass / glass wool. Then place a short blunt of copper pipe partially embedded in fibreglass at the top. The higher the tube is the higher become the flame - two millimeters are good. If the pipe stick up more than this can the flame be very high - up to the double length of the burner is no problem. The pipe is then filled with fine sand, but on the top lays copper powder or cuttings. Even outside the pipe will it be cuttings. The hot copper layer catalyses the combustion so that only an inconspicuous amount of unburned residue is passes.

Today's naphtha-based lighter fluids are more and more like lamp oils. From an operational point of view is it only positive if one can choose to drive with 20% n-paraffin (lamp oil) for the same price as for yesterday's fluids.

If one dosing 0.5% red glycol (type G+) in a batch of E80N so will it means a further improvement of the indoor air. The glycol (which is similar to G14a) has shown positive effects and can be recommended. However, avoid water in E80N!

The new EHB-C1 Heater Box is equipped with this type of burner that can be studied more closely by selecting ”H e a t e r B o x” on the top.

This is what E80N consist of

- 80 volume percent E85 or E75

- 10 volume percent naphtha based lighter fluid

- 10 volume percent lamp oil

- Also red concentrated ethylene glycol can be dosed 0.5%, which gives better combustion

Curiosities

An advantage with E80N is that it not build up pressure in closed containers. Probably the level of naphtha prevents this. The energy content of E80N is slightly more than E85 and depends on whether it is summer or winter quality. Somewhere around 33 MJ/kg I would bet on. If one reducing the naphtha content is a risk of uneven combustion - heater behaves erratically, which can result in unpleasant surprises. Increasing the naphtha is the reverse: The heater is doing its job ie burns evenly and stably. How to light an EHB? A cigarette lighter will do. The time it takes before you can light a burner depends on how wet the burners were before you put the plugs on the last time the heater was used. After the tank is filled with fuel must one usually wait a few minutes before it reached the sand bed. One can actually see when the sand get wet of fuel. And how do I turn it off? Simple - just blow out the flame. If one has the time and inclination so would one build a small special board for the fire unit with a shelf underneath where the bottles could stand. The ways how everything can be arranged or designed are probably many.

|

| |

|

| |