Test runs with i¤b with both petrol and E85 in an ordinary station wagon has been carried out without any direct positive impacts being identified. Any test with i¤b in diesel have not been implemented yet.

I have long tried to develop a fuel-soluble iron salt that also can serve with my additives. Before ”i¤b” appeared had I already developed MCO20 and omega-Fe. MCO20 creates an iron trioxide layer - that is clear. Regarding omega-Fe am not certain but probably also this results in a layer, but the main effort with omega-Fe is the lubrication of the cylinder walls. MCO20 is intended for E85 plus an external glycol additive, while omega-Fe only works for petrol. I¤b in the other hand works for both E85, other alcohols, petrol and diesel - it is at least certainly to enrich any of these with iron at any time. Before I found i¤b I studied other iron salts such as ferrocene (probable the component in MPG-Caps), McMT and pentacarbonyl. They are usually difficult to manufacture itself. German's BASF however, has long produced pentacarbonyl for use in inductive components. Common to these is that they are octane-enhancing. Read more on the site ferrocene about just ferrocene. Picrates is often referred to ”increase fuel milage”, which should be studied more closely in the future.

”i¤b” is an abbreviation for ”iron” and ”benzoate” and ¤ (sun sign) in between illustrate the benzene ring (although something unknown), which is typical of benzoates or different cyclic hydrocarbons. We are talking about iron benzoate - another variant of the preservative sodium benzoate. A somewhat tricky substance that has been blamed for various ailments. Sodium benzoate occurs at eg soft drinks - thus: cyclic hydrocarbons... Metallic benzoate salts however are easy to make yourself which one should consider when to operate a ”do it yourself site” of this kind. All you need is water, sodium benzoate and a metal sulfate. Exactly what type of iron benzoate I got out is unknown. There are some variations and the most common is iron-3-benzoate.

If one comparing so-called MPG-Caps or fuel pills with i¤b is the difference that I have chosen the liquid variety. The advantage is that it more quickly becomes distributed in the fuel if the iron is dissolved in for example alcohol before it is dispensed in the tank. Moreover, it is difficult to manufacture pills with only the soluble component credited. Its possible but requires that one can distil a salt carrier such as ethanol - collect - distilling etc. Here we can dosing an teaspoons i¤b in one deciliter (3 oz) and then filter it in a simple coffee filter. I¤b should be incorporated in dEC+ for petrol. AT2 or possibly hoGA for E85 and for diesel: isopropanol. Although additives A40 and ISO can keep i¤b. For petrol engines seems the most optimum to incorporate omega-Fe with A40 and i¤b in dEC+. Both (omega-Fe and i¤b) work together, but also ferrocene can coexist.

Performance

Dried iron benzoate after filtration/washing. When the filter paper absorbs iron benzoate during drying, one should save

it.

Dried iron benzoate after filtration/washing. When the filter paper absorbs iron benzoate during drying, one should save

it.The carrier is thus a fuel additive which is to be prepared with this iron salt. The color tone is revealing and like omega-Fe darkens the carrier significantly.

Never use i¤b in gasoline or ethanol vehicles along with IPA. IPA (isopropanol) should only be used if one wants to enrich diesel with iron. My experience with IPA in petrol or E85 is that it neutralizes the effects of other additives. IPA is not a bad additive as it dissolves unwanted substances and water very good, but as I said, one should avoid it as far as possible here. On the other hand, in diesel fuels - IPA is the savior number one. Unfortunately is the methylated spirits one can buy today already prepared with a minor part of IPA. That means, dEC+ will be holding some IPA whether one like it or not. To avoid IPA so is it certainly worth to look for those brands that do not contain IPA. This can be a little detective work in itself, to find them.

Good solvents for i¤b are: methanol, ethanol, acetone and IPA. Gasoline, toluene and other cyclical solvents are good carriers. Different naphtha products including diesel are sparingly soluble carriers - such as glycol and water also is. Then benzoates often have a low melting points can warm liquids (including Water) causes that a benzoate will be solved.

The content of iron in the fuel depends on the type of additive, and how much it dispenses.

Preliminary investigation

The sodium benzoate must be obtained and the fastest way to find it is at on the spice rack, larger quantities can be ordered through eBay. Paint shops are providing iron sulfate. It is used to paint wooden exterior with - the wood closest the surface die and turns gray, which protects against decay. Thus, iron sulfate with seven water molecules: FeSO4* 7H20 (copperas).

Plain tap water can be used. The salts that already are solved in the water and the formed sodium sulfate is sparingly soluble in for example ethanol. If one use methanol as a carrier so can one expect that even other trash including iron benzoate gather in the fuel tank. If one on the other hand choose gasoline, toluene, benzene, xylene, etc. as a carrier, then one can be sure that only the long non-polar molecular groups will be solved.

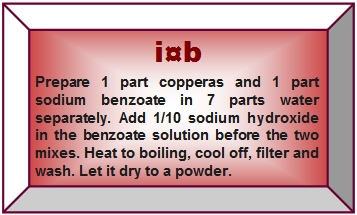

Production of i¤b

Both benzoate and iron sulfate shall be dissolved in water separately and apparently has the two about the same solubility. The necessary amount of water to dissolve the components is about 3.5 times the amount of powder. Example: 10 grams benzoate powder then requires 35 ml of water (same with iron sulfate). Here we choose to increase the amount to 7 times the amount of powder, which is needed because it all as well will ferment during the formation of iron benzoate (i¤b).

An old coffee carafe with heat-resistant glass is a good reaction container as it after a few rounds forms hard iron deposits inside the container. This should not your ordinary utensils and maybe your lab glass get exposed for. In the carafe should iron sulfate be prepare with water. The sodium benzoate will be prepared in another container, in addition will the sodium hydroxide be added and that along with the sodium benzoate. Be sure to stir well until all powder is dissolved in the water!

The in water dissolved sodium benzoate (plus hydroxide) are then slowly stirred into the water dissolved iron sulfate at the carafe. Then this will be heated to boiling. When it has boiled a moment one can allow it to stand and cool for at least two hours, preferably longer. When it's cold, it's time to wash off all the water-soluble salts from the reaction mass and then you can use a coffee filter. Add cold water in the mass, stir and then down in the filter. Continue pouring clean cool water on the mass in the filter so that no water soluble salts can exist there longer.

The last step is to gently dry the mass in an oven. Around 210-230 F is enough. It can be noted that a significant reduction in volume occurs! The weight of the dried powder is quite close to 30 % of the total initial weight which means that 70 % of the salt disappeared in the wash water. Iron benzoate has a low melting point but one do not win anything in weight to let it dry in air. If so, a good tip is to use a computer fan. This type of evaporation will of course takes a bit longer then. The residual filter paper can be cut into small pieces which one put in the carrier (the fuel additive) and then wait for the color change.

Citric acid appears cleaning of vessels and molds that boarders i¤b, but oxalic acid take away basically everything, though it may take a while.

Using a letter scale may seem exaggerated but facilitates of course the preparation. The lye should be dissolved in appropriate

amount of water before the benzoate is added (29g benzoate/sulfate here).

Using a letter scale may seem exaggerated but facilitates of course the preparation. The lye should be dissolved in appropriate

amount of water before the benzoate is added (29g benzoate/sulfate here).

The reaction takes place immediately during the mixing operation - one should stir continuous. Consumptions of water here:

2 x 200 ml.

The reaction takes place immediately during the mixing operation - one should stir continuous. Consumptions of water here:

2 x 200 ml.

Time to heat.

Time to heat.

Cooled (after 12 hours).

Cooled (after 12 hours).

Fluff up the mass with a little water and stir - before filtering begins.

Fluff up the mass with a little water and stir - before filtering begins.

Washing in a coffee filter at a smaller model. A greenish tinge may discernible.

Washing in a coffee filter at a smaller model. A greenish tinge may discernible.

The wet mass may be dried in a normal household oven (type 210-230 degrees Fahrenheit).

The wet mass may be dried in a normal household oven (type 210-230 degrees Fahrenheit).

16.4 grams of total 58 grams salt was the result. If one adds that were dried in the filter paper, we have 17.6 grams.

This is 60% by weight of the iron sulfate.

16.4 grams of total 58 grams salt was the result. If one adds that were dried in the filter paper, we have 17.6 grams.

This is 60% by weight of the iron sulfate.

A basic solution is necessary for that the reaction should go into the right direction, but instead of lye can one also use ammonia and then can 1/5 of the benzoate amount consist of type 25-percent ammonia solution.

I¤b components

- 1 part (weight/volume) powder iron sulfate

- 1 part (weight/volume) powder sodium benzoate

- 1/10 powder sodium hydroxide by the amount of sodium benzoate

The ratio of the components is approximately, but an excess of benzoate is preferred than vice versa. After several attempts, one can observe that the amount of sodium hydroxide is quite optimal. If then the weight of benzoate is 29 grams so will the weight of sodium hydroxide be close to 2.9 grams, and thus in agreement with the above demonstration. Small variations may occur regarding the amount of hydroxide but rather more than less.

Regarding sodium and iron sulfate: dissolve in cold water separately. The sodium hydroxide is dissolved with the benzoate. Water factor = 7.

Obviously will one saves some electricity to dry through a computer fan. All that one needed is a fan and a plate of plexiglas.

Then it can sit there and hum a few days - in an inconspicuous place.

Obviously will one saves some electricity to dry through a computer fan. All that one needed is a fan and a plate of plexiglas.

Then it can sit there and hum a few days - in an inconspicuous place.

From a powder to a liquid

Just ethanol is particularly suitable for i¤b. Ethanol dissolves the combustible iron benzoate good while it excludes uninteresting salts. Methanol is too good and solves willfully every possible both useful and useless things. Acetone is well located slightly to the ethanol direction too.

Unlike omega-Fe, we avoid separating the sneaky iron hydroxide when doing a iron additive with i¤b. You just put the powder in the solvent, let it stand for a while and then filter out the sediment. The result is a dark but clear liquid that immediately can be put into use.

- Measure the solvent/fuel additive to be enriched with iron in a bottle

- Add one teaspoon (5 ml) Powder per deciliter (100 ml) solvent in the bottle

- Shake the bottle and let it stand for a day or longer

- Filter the iron-enriched solvent in a cardboard filters (coffee filter) into a second bottle

|

| |

|

| |